Booming demand in the electronics sector

The advancing digitalisation is causing an extreme increase in demand for products from the fields of electronics and electrical engineering across all industries. From automotive to medical technology to the financial industry, demand will increase significantly everywhere by 2025.

All are either directly or indirectly dependent on a functioning supply and price stability of electronic parts such as semiconductors, PCBs or microchips. Meeting this demand is the great challenge facing the electronics and electrical engineering industry.

Procurement departments are facing major challenges

In the short term, a significant increase in supply is not to be expected, as building new capacity in the semiconductor industry takes a very long time and is very expensive. In the short term, it is therefore a matter of covering demand as best as possible. The buying price is quickly pushed into the background. Not only the excess demand, but also the scarce availability of raw materials, especially for rare earths, lead to increased price pressure even in times of normal demand.

In addition, development cycles are shortening, especially in sectors where innovation is a key growth driver, such as the electronics industry. The complexity of requirements is increasing rapidly due to fast-moving markets, which makes long-term optimization even more difficult. As a procurement organisation, keeping up with this pace and staying up-to-date is critical to survival.

How do we support companies in electronics and electrical engineering?

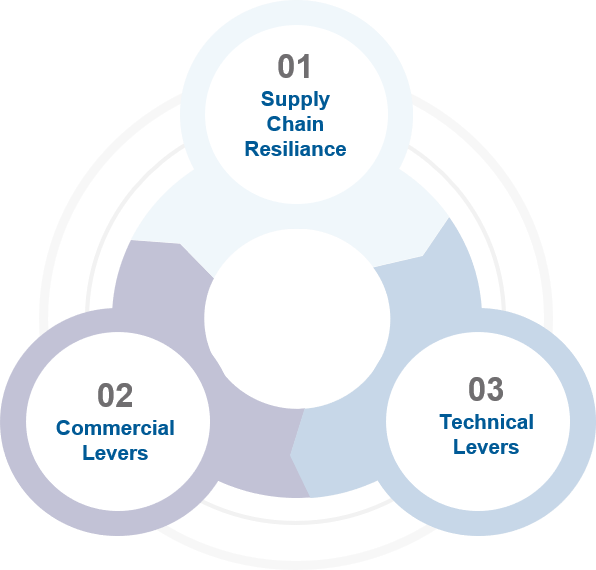

To optimise the resilience of the supply chain, we develop customised risk management processes and tools for you. In the first step, we look at your supplier structure far beyond the level of upstream suppliers and thus create the necessary transparency. In the second step, we support you in implementing concrete measures, such as securing the requirements of key components directly from the manufacturer or securing the supply through active lifecycle management for installed components.

We help you to make the entire demand planning process as flexible as possible. By intensifying cooperation across the entire supply chain, the speed of information exchange can be increased in order to react more quickly to fluctuations and disruptions – without burdening the cost situation.

The competitive situation varies from one electronics sub-product group to another. In times of supply bottlenecks in some sub-product groups, commercial aspects quickly fall behind, making it all the more important to exploit the full potential of commercial levers to ensure one’s own competitiveness. With our results-oriented procurement toolbox, from Asia Sourcing (e.g. for PCBs), game-theoretical negotiations or auctions (e.g. for B/C components) to R&D partnerships with selected partners for highly specific components.

To make commercial levers more usable and reduce supply chain risks, technical levers are indispensable. We support you with design-to-cost considerations or with the re-design of your electronic modules. For example, by switching to newer components, we achieve cost advantages at component level and at the same time reduce the risk of EOL (end-of-lifetime) situations. By harmonising components, we can achieve price advantages through quantity effects, a leaner supply chain, lower tool costs and testing efforts.

Our experts in the field of electrical engineering

Our insights from the electrotechnical industry