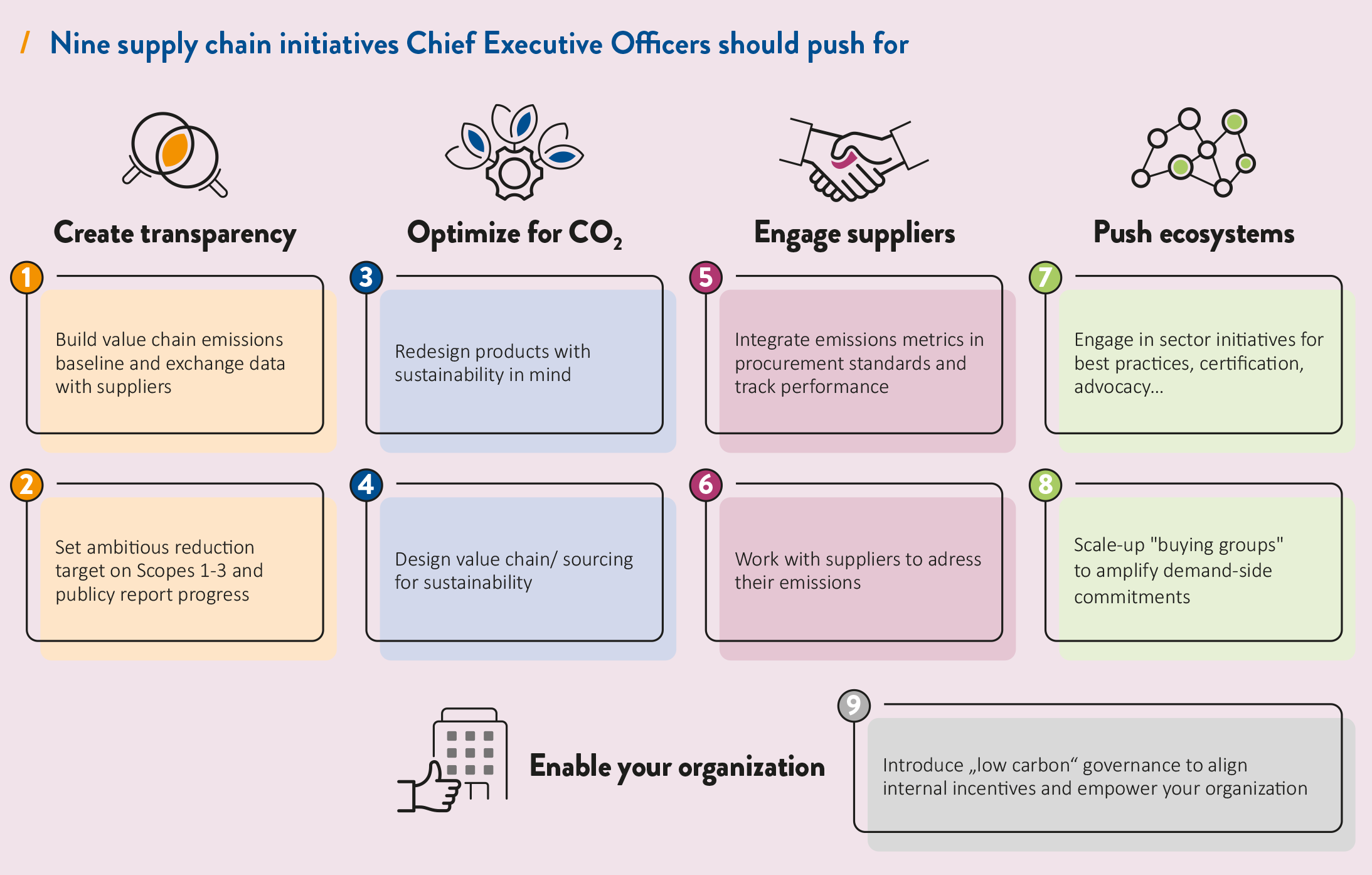

Not only does digitization help to accelerate transformation, modern tools can also bring about increased transparency and measurability across the supply chain. The use of analysis tools begins with raw materials. To be able to create transparency in this, it is essential to have information at hand about which raw materials are contained in the end product and in what proportions. It’s only by knowing the proportion of raw materials that procurement can get ahead in price negotiations with suppliers and agree advantageous index clauses.

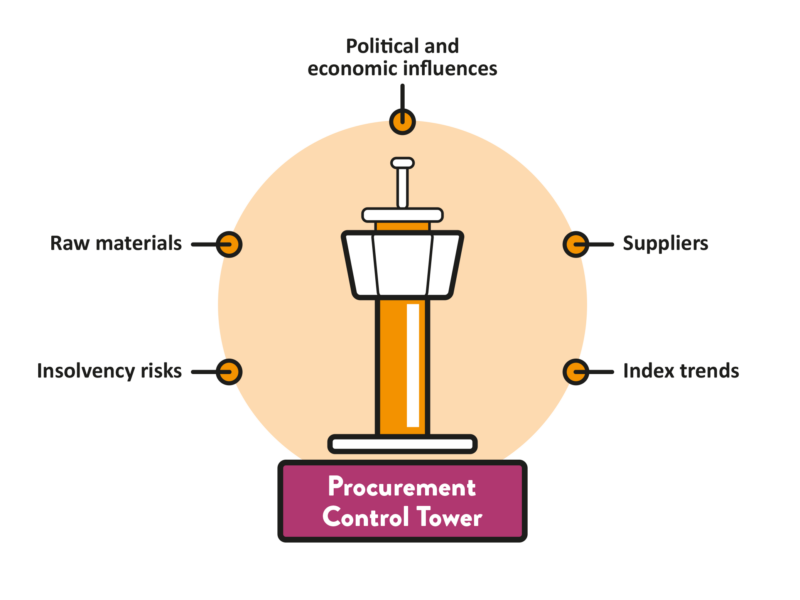

The fact that, on average, not even 50% of the supply chain has been digitized up to now means that resources urgently needed by companies are being wasted. So it makes sense to establish a control tower that provides a quick, automated overview of important suppliers, raw materials, index price changes and insolvency risks. If all this information is gathered in one place, the procurement department can define strategic options about what to do if a supplier lets them down: what mitigation plans are in place? What dual sourcing strategy needs more development?

In the best possible scenario, this transparency offensive should be extended so that companies and suppliers share data with each other too, from current stock levels to carbon emissions. For example, if a company is aware that the magnesium stocks in a supplier’s warehouse are running low, it can secure the supply at an early stage, or even support the supplier in the search for new sources.

Transparency is by far the most significant factor for transformation: it means goals can be reprioritized at procurement level. Specific goals relating to value creation can, for example, improve supplier performance or cost savings through better product design. It can make sense to develop nearshoring options, to make the supply chain more stable and sustainable.

But as these goals are often diametrically opposed, procurement has to find a balance depending on its priorities and keep recalibrating them as they can keep shifting, depending on the political and economic situation worldwide. For example, in the automotive industry, at the moment it’s crucial for companies to obtain semiconductors, and now the supply chain has been affected again as a result of the Ukraine crisis. In this current situation, resilience takes priority over cost optimization or value creation.

Companies must ask themselves how they can balance trade-offs, especially for long-term, strategic decisions. The search for alternative raw materials plays just as important a role as strategic collaboration with suppliers.

Procurement also has to manage trade-offs when it comes to sustainability. For instance, many companies are currently working on initiatives to relocate supply chains and to regionalize; even though production in Europe is often associated with higher costs, it can help to significantly minimize delivery problems. With shorter distances, different means of transport and higher environmental and social standards in domestic markets, this can also make sense from a sustainability point of view.