In order to implement the legal requirements, it is advisable to take a step-by-step approach that starts within your own company.

The Supply Chain Act

Transparent Relationships

Looking after the climate and the environment, preventing exploitation and child labor: these things should be a given, in theory, but to date not all companies have known exactly what is going on in their own supply chains. Supply chain regulations offer an opportunity to finally create clarity and binding rules. Some countries, including Germany, have already passed legislation, and now the EU is following suit.

The economy is currently split into two camps: those who fear additional burdens because they are worried about more bureaucracy and duties, and those who see it as an opportunity. We’re on the side that’s expecting positive outcomes from this law.

We think that companies will particularly benefit from setting up their risk management more broadly to meet the law’s requirements. Professional and strategic risk management makes it possible to be more resilient and agile when risks occur. And this in turn means companies can create more value and be more competitive.

We recommend taking a step-by-step approach, starting in your own company, to implement the new legal requirements. Check which requirements you already meet, for example through a sustainability agenda or compliance regulations. Are these requirements stringently implemented within the company, particularly when it comes to your procurement strategy and risk management? Unfortunately, we often see that there may be goals and statements, but these are not actually reflected in the individual departments. Training,building awareness, and also incentivization, are important in this context to help employees comply with the Supply Chain Act.

Once the internal requirements have been clarified, the law stipulates that the company must first adopt a policy statement covering the new due diligence requirements. Using a risk analysis, potential problems can then be identified and categorized, and countermeasures can be defined. If strategic risk management is already in place, it will be easy to expand your current criteria to include the legal requirements.

In order to implement the legal requirements, it is advisable to take a step-by-step approach that starts within your own company.

Implementing the Supply Chain Act is a task that requires cross-company collaboration as it also involves corporate communications and your legal department, because as well as the supply chain requirements, the law also requires companies to inform the public about risks and solutions, as well as to establish a public complaints body. So the task force in charge of implementing the law and managing the internal communication flow should be interdisciplinary.

Risk management that will meet the law’s requirements should include prioritizing countermeasures: is the violation so serious that your company should stop working with the supplier immediately? And what are the possible solutions?

It goes without saying that contingency plans and countermeasures need to be planned in more detail and communicated more actively than before the law was introduced.

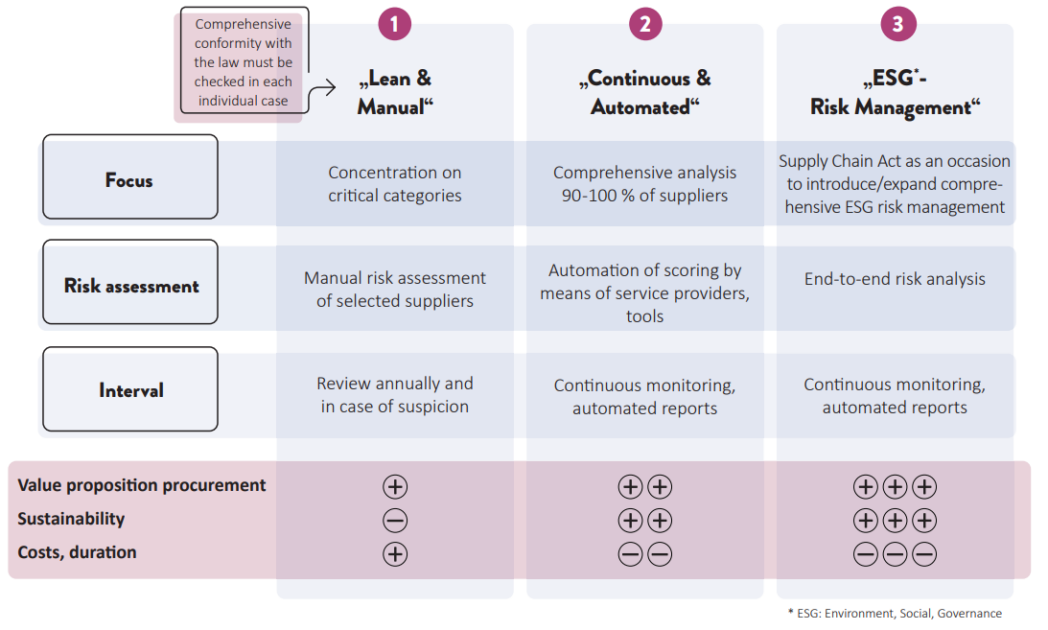

The next step towards implementing the act is talking to suppliers. Again, it’s important to use your current situation as your starting point. Expand existing audits or specifications to include the legal criteria, and make sure you discuss everything with suppliers. Clarify where your suppliers perceive risks and compare them with your findings. Define possible solutions and countermeasures together for the downstream supply chain. Involve independent organizations, for example NGOs or auditing companies, in audits. Depending how far along you are in developing your own sustainability goals, we’ve developed three models of varying complexity that you can use as a basis for implementing the Supply Chain Act requirements.

Some companies have already been taking responsibility for their supply chains for several years and are continuously working on improving conditions for their suppliers’ employees or implementing optimized environmental protection measures. Companies now required to do so by law can learn from them. We’d like to present three companies of differing sizes and business sectors as examples.

For example, the fashion retailer Takko proves that realizing ESG criteria in its own supply chain is possible, even in the lower price segment. The company’s managers emphasize that low-cost production is achievable, not through unfair wages or child labor, but through streamlined processes, large quantities and efficiency in design.

A draft European Supply Chain Act was presented in the EU Parliament at the end of February. It is far stricter than the German one and also applies to more companies. If passed, all EU countries would be required to implement the law. The draft includes the following regulations:

The retailer Tegut, on the other hand, relies on direct and long-standing supplier relationships for its own brands and for fresh products, so it can sell organic and fair-trade food to its customers. The company also offers maximum transparency with the “Origin Check” facility on its website. There are numerous suppliers, each with their own profile, in full view with this feature.

The cosmetics, household goods and adhesives manufacturer Henkel has received many awards for its commitment to the environment and employees’ rights. The company has an ambitious agenda that includes gender parity at all management levels by 2025, and a carbon positive footprint and transition to a circular economy by 2030. In its supply chains, the consumer goods manufacturer has set itself the goal of “100% responsible sourcing”.