Unlock the potential of supply chain management with our versatile solutions that cater to a wide range of industries and commodities. Our approach facilitates a seamless transition to alternative markets, ensuring a gradual and effective conversion for your business success.

Adapting to the red sea crisis: strategies for supply chain resilience

The escalation of Houthi attacks in the Red Sea has forced shipping companies to reroute vessels around Africa, significantly impacting global supply chains. In December 2023, the effects were massive: extended transport time, increased costs due to rerouting and volatile freight prices. Sea freight prices peaked at around $4,000 per container but have since decreased by 25%. As prices continue to fall, it’s time for organizations to re-negotiate and gear up for the impending rebound.

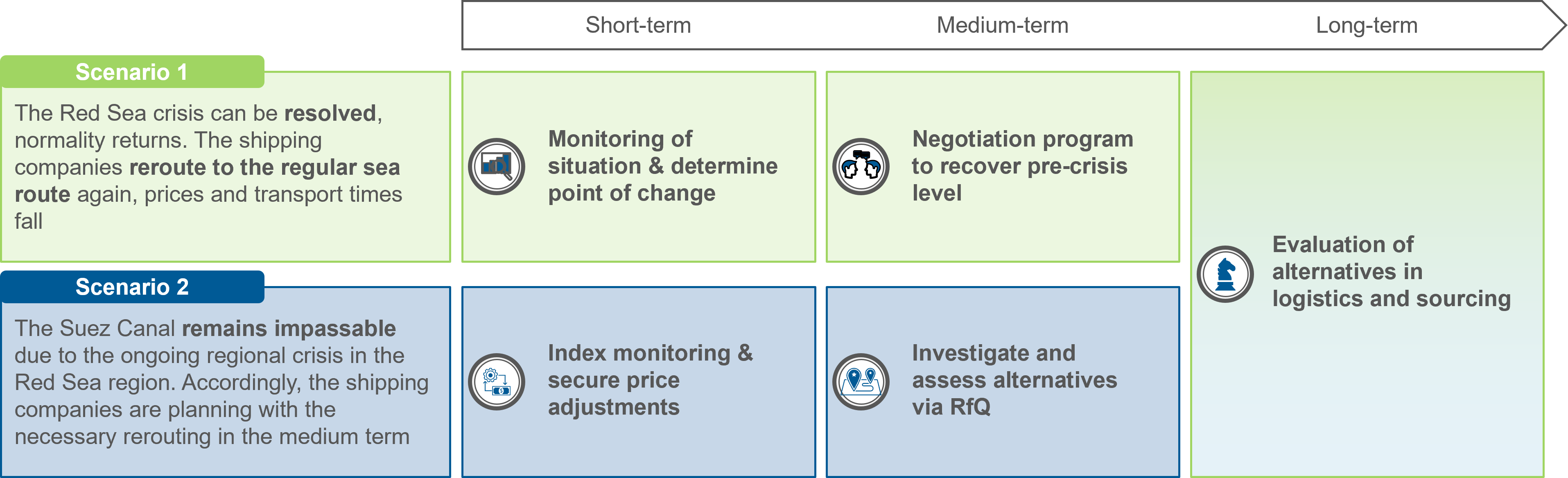

Near-future scenarios and customized solutions for optimal value protection

Mitigating bottlenecks: advocating close monitoring and strengthening supply chain resilience

Monitoring of situation & determine point of change

- Evaluate if used routes are affected by the resolution of the red sea distraction (Continuous Monitoring)

- Evaluate spot market prices and benchmark against current conditions

Index monitoring & secure price adjustments

- Monitoring of the indices and the spot market to determine the actual price level

- Evaluate the costs with the rerouting of the sea-freight against the cost of switching routes and transportation modes

Negotiation program to recover pre-crisis level

- Conduct rapid and data-based negotiations to restore the pre-crisis price level with incumbent providers

- Conduct sea freight RfQ to challenge incumbent providers and

Investigate and assess alternatives via RfQ

- Assess alternative modes like rail freight and route mixes (air-road-ocean) e.g. via Jebel Ali Airport via a door-to-door RfQ without any restrictions regarding lanes or modes

- Evaluate freight costs against lead time improvement

Evaluation of alternatives in logistics and sourcing

- Evaluate buffer stock building through internal/external warehousing options

- Adjust the S&OP process to reflect increasing delivery time

- Assess your category portfolio to pinpoint commodities suitable for nearshoring

- Prioritize re-/nearshoring to boost supply chain resilience, reduce CO2-emission and lower product price

Tailored solutions ready to assist in managing the challenge

- Evaluation and classification of actual and potential risks

- Derivation and prioritization of concrete measures

- Quick analysis of current situation and rapid negotiation to unwind price increases

- Balance increased freight cost by realization of commercial and technical levers e.g door-to-door RfQ

- Build an analytical model of your supply chain network to re-design/ adapt your footprint to new conditions

- Empower your S&OP process with scenario planning tools to quickly react on criticalities

- Mapping supply networks to enhance supply chain visibility

- Assessment of categories to evaluate applic-ability, benefits & business case

Get to know our experts