Take the right action now

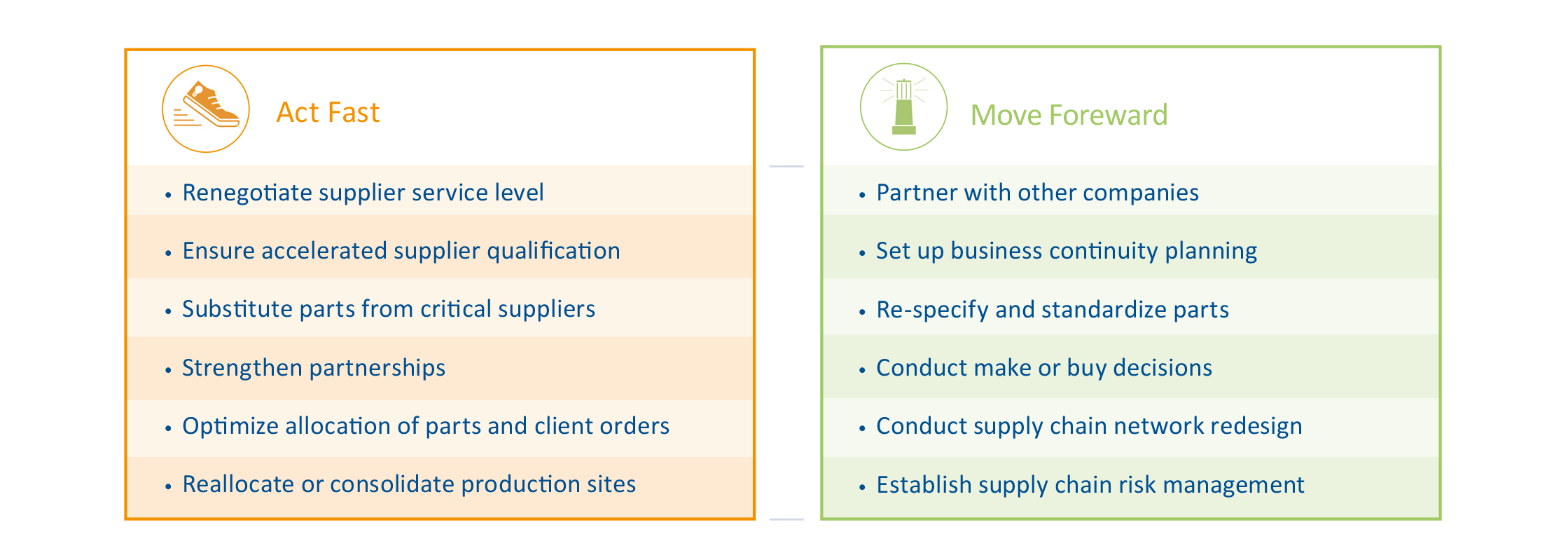

Act fast

Involve all internal partners in your risk management and establish a cross-departmental team: procurement, supply chain management, production, planning and sales. This task force coordinates all activities. Define internally which inputs are critical and what ranges must be in place. Coordinate within your existing tight supply chain and try to stay operational together with your supply chain partners.

Get transparency, if not already done, of the upstream supply chain: Do you know where your

suppliers produce and how their supply chain is structured? Where are delivery delays imminent and when might they first occur? In which areas of your production are you dependent on individual suppliers? If delays or failures threaten critical parts, you need to react immediately. Research and qualify alternative suppliers. It is important to ensure genuine diversification of the supply chain; therefore, also clarify the sources of supply of any alternative partners.

Regular discussions with logistics partners help in operational procurement. As long as sufficient stability has not been established, the task force should continuously monitor supply chains, inventories and logistics in order to be able to act immediately as required.

Move forward & beyond

Once the crisis team is established and working reliably, it is time to think ahead: pandemic, war and recession reinforce trends that were already noticeable before, such as protectionism and trade barriers. In the same way, the discussion about climate protection and fair production conditions within supply chains will not go away: Climate-related risks such as low water, floods or wildfires continue to increase.

Companies should take the current pressures as an opportunity to reorganize their

supply chain in terms of resilience and sustainability. The fields of action to realize this are:

- Establishment of strategic risk management

- Consistent digitalization

- Diversification of own supply chain, near- or reshoring if necessary

- Innovation partnerships with strategic suppliers

- A reconsideration of make-or-buy strategies

- Re-specification of critical parts and materials

Overview: Implementation of the actions

Our experts in stabilizing supply chains