Overtake the competition with your own standards

The past months have shown: Political crises, trade restrictions, currency fluctuations and many other external influences make efficient raw material procurement more difficult. External factors such as massively increased stock market indices and accelerated inflation have a much greater impact on success in commodity procurement than is the case with other commodity groups. Structured risk management should therefore be an integral part of any commodity strategy.

Particularly in the current situation, characterized by supply bottlenecks and volatile prices, you can create greater planning security and competitive advantages by establishing a professional commodity and risk management system.

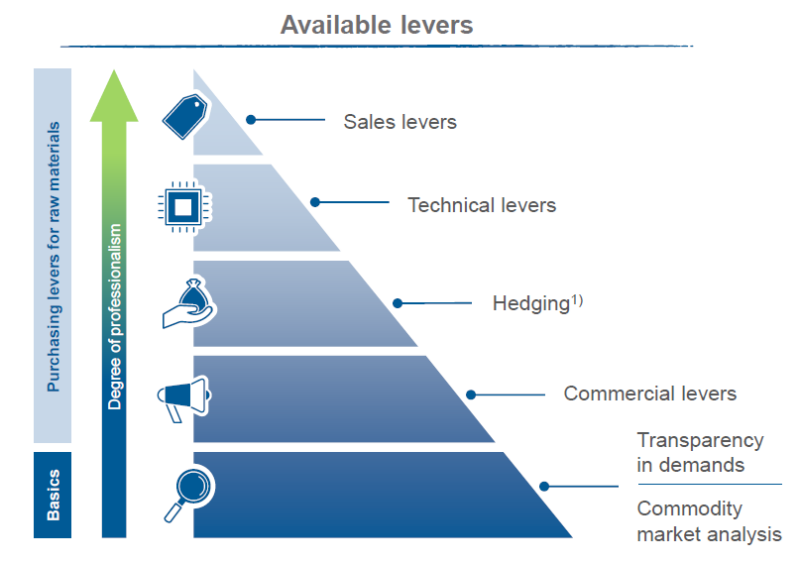

Usingour many years of consulting experience in raw materials procurement, we have identified the four most important levers thanks to which our customers are well positioned, despite the current difficult market conditions. We divide raw material management into sub-disciplines in order to build a fully comprehensive and sustainable raw material procurement system.

PROCUREMENT: LET’S GET REAL!

Our expert Justus on the topic of raw material management

In the coming months, despite the dislocations in international supply chains, buyers need to secure supply of all critical raw materials, while keeping costs under control. Given the rapid price increases in many raw materials and logistics. It is not possible to entirely avoid higher costs.However, buyers should take the time to check suppliers price requests.

This can be done, for example, with cost breakdowns in which the individual parts and the raw material content of a product are evaluated.

Most companies don’t buy the raw material itself, but products containing raw materials. On this basis, potentials for negotiations with the supplier can then arise. Buyers should realize that price increases are not just effecting their company but the market as a whole. In this situation, it can already be an advantage to analyze prices in detail and accept lower mark ups than other competitors. If you know the exact price composition, this also helps to pass on costs to customers. And later, when the raw material price level reduces, the product price composition is useful to negotiate the higher costs down again.

What we often experience are unspecific purchasing forecasts. Instead, to agree on binding uantities, only rough forecasts are communicated to suppliers and the required quantity is purchased short notice. However, when availability is limited and prices are rising, this strategy doesn’t work because the suppliers naturally first supply the customers with fixed contracts. To be fair, it is important to mention that thelimited market situation occurred very quickly.

As a result, some purchasing departments simply missed the right moment to implement the correct purchasing strategy. Additionally, not all companies operate strategic risk management systems and very few use digital solutions. This is a pity, because of course digital support and risk management takes time and investment to set up but in the long run, early warning mechanisms pay off, simply because they give time for a well-structured reaction strategy in the event of a crisis. To further expand commodity management in the current, geopolitically uncertain times companies should increasingly conduct supplier audits to guarantee continuous supply security.

Moreover, close internal cooperation is key, especially when passing on raw material costs to customers. Procurement and sales should work in close cooperation so that purchasing price changes are incorporated in sales prices.

The relevance of this purchasing level is also present in our current raw materials study that we conducted with around 100 different companies. 60% of all participating companies stated that passing on rising raw material costs is essential to keep raw material management under control.

Raw material prices became much more volatile, and suppliers don’t want to take any price risks, which is why suppliers only accept fixed prices for very short periods. This is also reflected in our current raw materials study.

In 2020, only about 10% of all participating companies were affected by strongly short and fixed price periods, whereas this year around 60% of all participants are effected. Companies should address the cost issue with their suppliers and a cooperative manner.

After all, the price increases are real. Only the price requests that suppliers derive from them are not always real. It makes sense to agree on a price escalation clause that is based on stock market indices. A price escalation clause is a win-win situation for purchasing companies and suppliers, as changes in raw material prices are more transparent and it reduces the effort of regular renegotiations. On the other hand, purchasing companies should not accept that suppliers pass on all costs 1 to 1, if the purchasing company doesn’t have that option itself with their customers.

Therefore, procurement teams should agree on a fair pain sharing with their suppliers, where everyone bears a share of the additional costs.

How do we go about advising on raw material procurement?

In the raw material market analysis, on the one hand, the market development of raw materials and on the other, the market of raw material suppliers are continuously analyzed by our raw material experts. Thanks to our in-depth knowledge of raw material management, our data is always up-to-date and ranges from raw material requirements for the food industry or the pharmaceutical sector to industrial goods, the automotive industry or the electronics industry. In addition, we create demand transparency in your raw material procurement in order to achieve the best possible efficiency in procurement optimization. In doing so, we perform quantity and cost breakdowns, create a raw material spend matrix and broaden your perspective by creating transparency across your supply chain.

Commercial levers include demand-specific tenders and corresponding negotiations to identify suitable alternative suppliers for your requirements. In the process, individual contract designs are developed andare predominantly aimed at securing stable supply security at optimal costs.

Hedging is a proven solution to protect against price fluctuations and supply bottlenecks. We distinguish between physical hedging, operational hedging, supplier hedging and financial hedging. Targeted hedging measures minimize price and supply risks. We work with you to develop and implement the appropriate hedging strategy for your raw material procurement.

The use of technical levers opens up additional potential in cost management and ensures a reduction in raw material dependency. We achieve this by reducing the use of raw materials, reviewing and, if possible, using substitutes and developing new products.

Aligning procurement and sales strategies offers additional potential for minimizing price risks. Our raw material consultants support the specialist departments in the joint development of strategies. Coordination between procurement and production and open-book costing harmonize price conditions and ideally pass on risks to customers. The targeted sale of alternative products also ensures greater security in your raw materials management.

Raw materials workshop

An intensified use of recycled materials would reduce Europe’s dependence on the countries where the raw materials are stored or refined.

Justus Brinkmann, Senior Project Manager, INVERTO Munich

The results

- Cost optimization in raw material procurement

- Minimization of raw material risks (supply and price risks) through optimization of existing as well as negotiation of new supplier contracts

- Establishment of tools and knowledge to ensure long-term stable raw material management and rapid responsiveness to market changes

Our raw material experts